- BUTTERFLY VALVE

- PNEUMATIC BUTTERFLY VALVE

- MANUAL BUTTERFLY VALVE

- ELECTRIC BUTTERFLY VALVE

- BALL VALVE

- PNEUMATIC THREE-PIECE BALL VALVE

- MANUAL THREE-PIECE BALL VALVE

- PNEUMATIC STRAIGHT BALL VALVE

- MANUAL STRAIGHT BALL VALVE

- PNEUMATIC THREE-WAY BALL VALVE

- MANUAL THREE-WAY BALL VALVE

- CHECK VALVE

- SPRING CHECK VALVE

- AIR RELEASE VALVE

- AIR RELEASE VALVE

- VACUUM SAFETY VALVE

- SAFETY VALVE

- DIAPHRAGM VALVE

- PNEUMATIC DIAPHRAGM VALVE

- MANUAL DIAPHRAGM VALVE

- THREE-WAY DIAPHRAGM VALVE

- SAMPLING VALVE

- SAMPLING VALVE

- ASEPTIC SAMPLING VALVE

- SIGHT GLASS

- STRAIGHT SIGHT GLASS

- UNION SIGHT GLASS

- UNION SET

- DIN UNION

- SMS UNION

- RJT UNION

- ISO/IDF UNION

- CLAMP FERRULE SET

- CLAMP

- FERRULE

- END CAP

- HOSE COUPLING

- FERRULE GASKET

- PIPE HOLDER

- ROUND PIPE HOLDER

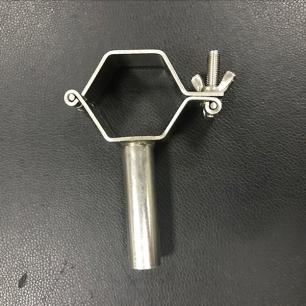

- HEXAGON PIPE HOLDER

- SPRAY BALL

- ROTARY SPRAY BALL

- FIXED SPRAY BALL

- ROTARY CLEANER

-

Clamp cross

Clamp crossThe company produces: DIN, SMS, 3A, BS, BPE, ISO2851, ISO1127 and other standard sanitary grade pipe fittings, and the product blanks are all formed by cold-pressing seamless pipes. All products can be processed with different surface roughness according to customer requirements.

All metal materials can provide EN10204, 3.1B certificates.

-

Clamp elbow

Clamp elbowStandards: DIN, 3A, SMS, BS, ISO, GB

Size: 1"-6" DN10-DN200 17.2-168.3

Metal material: 304, 304L, 316, 316L

Surface treatment: 1) 180 Grit

-

Quick-fit U-shaped connector

Quick-fit U-shaped connectorAdvantages: 1. Corrosion resistance

2. Not easy to rust

3. Strong versatility

4. High and low temperature resistance

5. Beautiful appearance

-

Hexagonal tube bracket

Hexagonal tube bracket -

Y-type filter

Y-type filterThe filter is used to prevent the solid particles in the filtered medium from entering the subsequent pipeline. After the medium enters the filter element of a certain size from the filter inlet, its larger solid particles or impurities remain in the filter element, and the filtered medium flows out from the outlet , Meet the requirements of use. When the pressure difference between the front and back of the filter exceeds the requirements or the filter element is damaged, just remove the filter element, clean it or replace the filter element, and reinstall it before use.